Consistent High Pressure

You can rely on our compressors for stable, high-pressure air, ensuring consistent and smooth blow molding operations without interruptions.

In the PET Blow Molding Industry, a steady and reliable high-pressure air supply is crucial for molding, shaping, and producing PET containers.

You can rely on our compressors for stable, high-pressure air, ensuring consistent and smooth blow molding operations without interruptions.

With robust, low-maintenance components, GiantAir compressors reduce downtime, allowing you to focus on maintaining your production schedules.

With robust, low-maintenance components, GiantAir compressors reduce downtime, allowing you to focus on maintaining your production schedules.

See how companies in the PET Blow Molding Industry have benefited from GiantAir’s High Pressure Screw Air Compressors

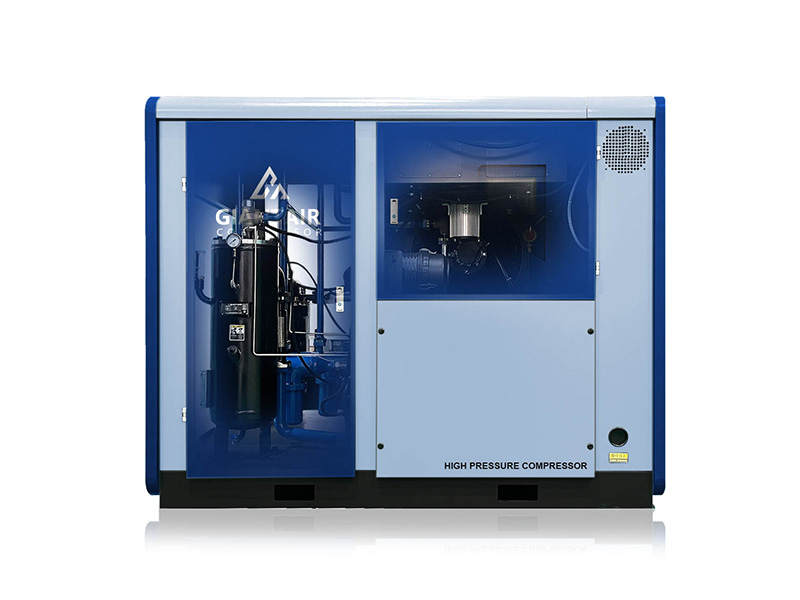

At GiantAir, we understand the demands of the PET Blow Molding Industry. Our High Pressure Screw Air Compressors provide you with consistent, high-performance air while keeping energy consumption low and maintenance minimal.

With our robust and durable compressors, you can rely on us to ensure smooth, uninterrupted operations that keep your production lines running at peak efficiency.

Our compressors provide consistent, high-pressure air for molding, shaping, and producing PET containers, ensuring smooth operations and improved production rates. Contact us to learn more about how we can optimize your process.

Yes, GiantAir’s compressors are designed to minimize energy consumption while delivering reliable, high-pressure air. Get in touch for more details on how we can help you reduce energy costs.

Our compressors are designed for minimal maintenance. Regular inspections and filter changes will ensure they continue running efficiently. Reach out to us for a maintenance schedule tailored to your needs.

Yes, our compressors are built for continuous, high-pressure operation, making them ideal for high-demand PET blow molding processes. Speak with our team to discuss your specific requirements.

With proper maintenance, our High Pressure Screw Air Compressors are designed to last for many years, providing consistent performance for demanding applications. Contact us to discuss how to maximize the lifespan of your compressor.

Yes, our compressors are designed for easy integration into your existing PET blow molding system, ensuring a seamless transition and optimized air supply. Let us know your current setup, and we’ll help with integration.