Compressors are essential in industrial performance. But they produce condensation during compressor cycles. An air compressor draws in atmospheric air. A small amount of water vapor collects in air tanks, storage tanks, and air receivers. If not removed, this water causes erosion, malfunction, and contamination of compressed air. Controlled drainage is essential in any industrial shop. It helps maintain dry compressed air and reliable motor performance. An auto drain valve for an air compressor provides this protection. It removes water mechanically without manual intervention.

What Is an Automatic Drain Valve?

An automatic drain valve is a motor-type device used in compressed air systems. It removes accumulated condensation automatically without manual effort. Condensation forms during every compressor cycle. Controlled drainage is important in an industrial shop. It protects the air compressor, tanks, motors, and downstream equipment from corrosion.

Manual drain valve vs automatic drain

- Manual drain valve requires regular operator attention and is often neglected.

- Automatic drain removes condensate consistently and reliably.

Role of Automatic Drain Valves in Water Management

Automatic drain valves control water levels. They collect water in the valve’s condensation reservoir. The water is released only when needed.

Key functions

- Maintain dry compressed air quality.

- Reduce erosion and setup wear.

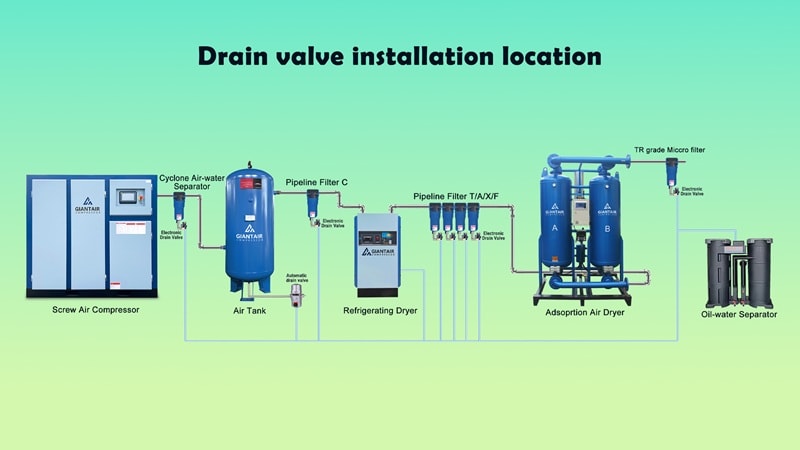

Typical installation points

- Air tank outlets

- Storage tanks

- Low points in compressed air setups

How Automatic Drain Valves Work

Automatic drain valves remove water efficiently. They do not disrupt normal compressor operation in an industrial shop.

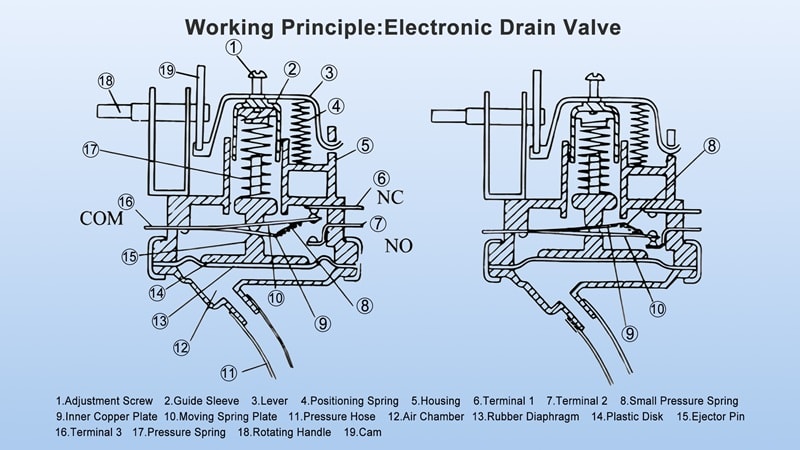

Basic Working Principle

Automatic drain valves detect condensate levels inside the valve body or condensation reservoir. As liquid accumulates, the pneumatic internal mechanism is activated to start drainage.

- Pneumatic piston uses pilot air from the compressor to generate opening force.

- The piston pushes or releases the internal ball valve.

- Once opened, accumulated liquid is discharged from the drain point.

Setup Efficiency Benefits

- Using automatic drain valves improves performance.

- Significantly reduced air loss compared to a manual drain.

- Continuous prevention of buildup during compressor functioning.

Comparing Different Automatic Drain Valves

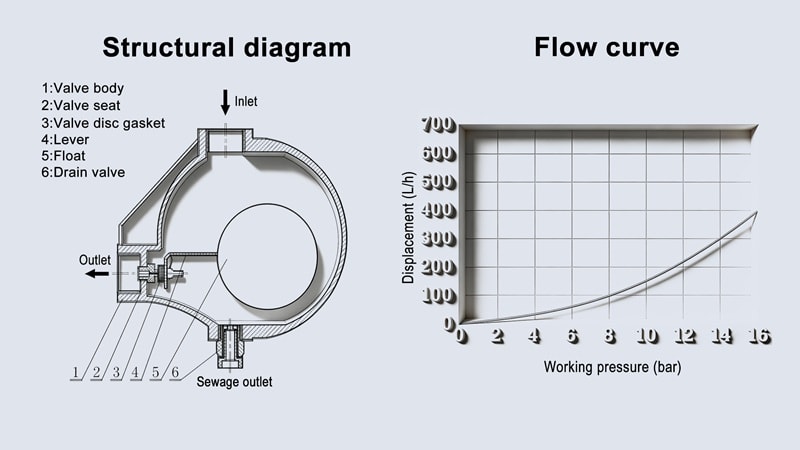

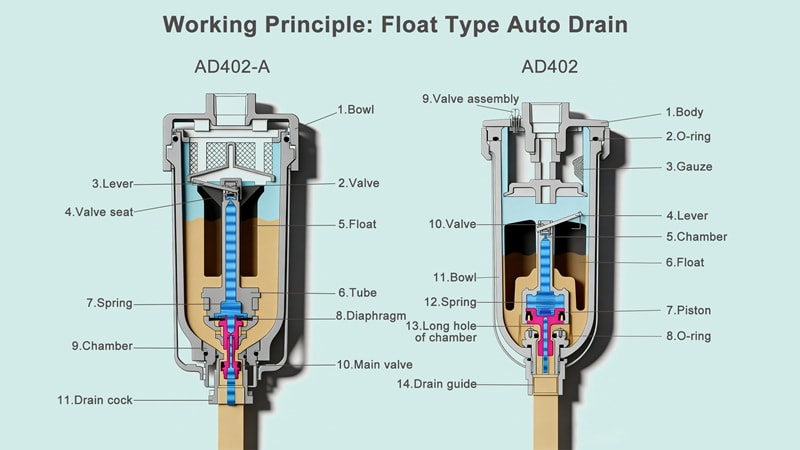

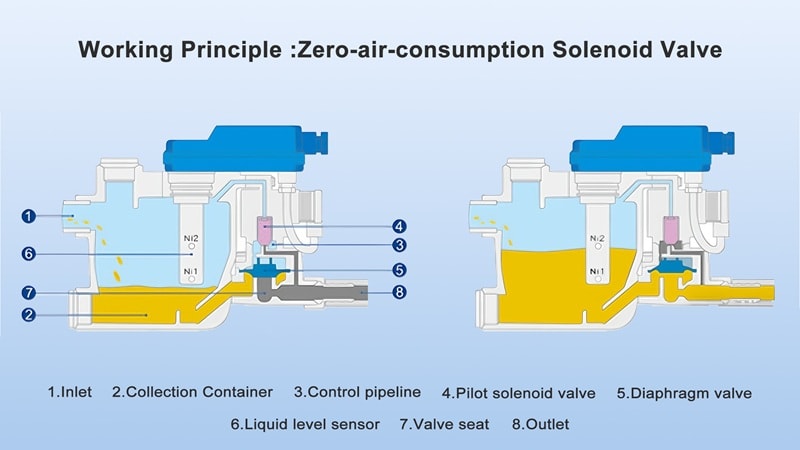

Float-type, timer-based, and zero-loss drain valves work in different ways. Each type responds to moisture differently. They also differ in air loss during discharge. In many designs, a ball valve opens and closes to release condensate. Pneumatic performance can change with pressure and temperature conditions.

| Drain Valve Type | How It Works | Advantages | Limitations |

|---|---|---|---|

| Float-Type Automatic Drain Valves | A float rises as condensate builds up. When the set level is reached, the float opens the valve and releases the liquid. | No power required, simple functioning, float responds directly to water levels. | Contaminants can affect the float. They may block its movement and reduce accuracy when pressure changes. |

| Timer-Based Automatic Drain Valves | A timer opens the valve aA timer opens the valve at fixed, scheduled intervals. | Low cost, adjustable timing, easy installation. | Risk of air loss if timing is poorly set |

| Zero-Loss (No-Loss) Drain Valves | Sensors detect condensation and trigger discharge only when water is present. | No compressed air loss, high energy efficiency | Higher initial cost |

Benefits of Using an Automatic Drain Valve

These valves control condensation effectively. They protect equipment, reduce malfunctions, and improve long-term efficiency.

Efficient Water Removal from Air Compressors

- Continuously removes condensation as it forms.

- Prevents water accumulation in tanks and piping.

- Maintains stable compressor performance.

Reduced Corrosion and Water-Related Failures

- Minimizes internal rust and surface damage.

- Reduces the risk of component and valve failure.

- Extends the service life of compressed air equipment.

Improved Air Quality and Equipment Protection

- Maintains clean, dry compressed air.

- Protects downstream tools, air dryers, and control systems.

- Reduces contamination-related performance issues.

Lower Maintenance Effort and Labor Costs

- Eliminates routine manually required draining tasks.

- Reduces emergency maintenance caused by buildup.

- Allows maintenance teams to focus on critical system work.

Cost-Effective Management Solution

- Reduces air loss compared to manual drain methods.

- Lowers long-term repair and replacement costs.

- Delivers reliable performance with minimal operating expense.

Reliable Performance in Industrial Environments

- Designed to withstand high temperatures and stress variations.

- Performs consistently in continuous-duty applications.

- Improves overall system accuracy while reducing downtime.

Choosing the Right Automatic Tank Drain

Selecting the correct automatic tank drain affects how efficiently condensation is removed. It also protects compressed air equipment. The right choice depends on actual system conditions, not assumptions.

Key Selection Criteria

This step focuses on matching the drain valve to real compressor operating requirements.

Valve Type And Compressor Compatibility

- Match the valve type to the air compressor size, duty cycle, and condensation.

- Ensure the drain is suitable for reciprocating or rotary screw compressors.

- Confirm compatibility with air tanks, air receivers, and system piping layout.

Thread Size and Installation Location

- Verify the exact drain port thread size on the air tank.

- Install the valve at the lowest condensation collection location.

- Maintain physical access for inspection, cleaning, and replacement.

Maximum Operating Pressure And Temperature

- Select a valve rated above the system’s maximum working force.

- Account for stress spikes during startup and shutdown.

- Confirm temperature ratings for continuous compressor functioning.

Flow Capacity And Discharge Duration

- Ensure the drain flow capacity matches peak condensation load and location.

- Set discharge duration to fully remove liquid without air waste.

- Avoid undersized drains that cause water backup and system issues.

Material and Construction

Valve materials determine durability, sealing performance, and resistance to contamination.

Valve Body Materials

- Brass valves are suitable for moderate pressure and standard industrial environments.

- Stainless steel valves provide higher strength and corrosion resistance.

Resistance To Oil And Contaminants

- Internal components must tolerate oil, water, and particulate contamination.

- Sealing surfaces should resist wear from frequent elimination cycles.

- Corrosion-resistant materials improve long-term valve functioning.

Cost and Long-Term Value

Long-term performance is more important than upfront cost alone.

Initial Cost Vs Operating Efficiency

- Lower-cost drains may increase compressed air loss over time.

- Efficient designs reduce wasted air and energy consumption.

Maintenance Frequency and Service Life

- Durable construction reduces maintenance frequency.

- Longer service life lowers replacement costs and downtime.

- Improved function protects the entire compressed air system.

Installation and Maintenance

Correct installation and routine maintenance are essential. They ensure reliable drainage and a long service life for an automatic drain valve. Proper setup ensures consistent condensation removal, while regular checks prevent blockages and failures.

Installation Steps (Step-by-Step)

Step 1: Shut Down and Depressurize the System

- Stop the compressor completely and isolate the power supply.

- Release all air pressure from the tank until the gauge reads zero.

- Never install a drain valve on a pressurized system.

Step 2: Prepare the Drain Connection Level

- Identify the lowest port on the tank or receiver.

- Clean the utilized port threads and remove dirt, rust, or old sealant.

- Confirm the correct thread size and valve orientation.

Step 3: Apply Sealant and Install the Valve

- Apply PTFE tape or approved sealant evenly.

- Thread the automatic valve in by hand, then tighten securely.

- Avoid over-tightening to prevent thread or valve body damage.

Step 4: Connect Discharge and Power (If Applicable)

- Route the drain outlet to a safe condensation collection spot.

- Connect electrical power for electronic or sensor-based.

- Verify voltage, wiring, and grounding before functioning.

Step 5: Configure and Test Performance

- Program timer settings or confirm sensor activation.

- Restore power and pressurize the system.

- Observe proper valve opening and discharge.

Maintenance Best Practices

Routine maintenance keeps the valve operating correctly and prevents water buildup.

- Perform regular inspection of vents to check for clogging or debris.

- Inspect sensors, wired timers, and vents for proper working.

- Verify that the valve opens and closes as intended.

- Confirm that condensation is discharged completely during each cycle.

- Schedule maintenance based on operating hours and load.

Factors Affecting Condensate Removal

Effective condensate removal depends on setup, operating conditions, and proper drain design. These factors affect water removal. They determine how well water is removed from the air compressor and pump.

Compressor Size and Duty Cycle

- Larger compressors generate higher condensate volumes.

- Continuous operation increases water accumulation.

- Frequent cycling can accelerate condensate formation.

Ambient Temperature and Humidity

- High humidity raises condensation moisture entering the setup.

- Temperature drops cause faster condensation.

- Cold conditions increase internal water buildup.

Condensate Load and Water Content

- Higher condensation content requires greater draining capacity.

- Oil and contaminants can slow condensate flow.

- Heavy condensate loads demand efficient drain valves.

Frequently Asked Questions (FAQs)

How is an automatic drain valve different from a manual drain valve?

The valve must be opened by an operator, which is often forgotten or delayed. An automatic drain opens on its own based on time, level, or sensor detection, ensuring consistent drainage.

How often does an automatic drain valve release condensate?

The drainage frequency depends on the valve type. Timer-based drains operate at programmed intervals, while float and zero-loss drains activate only when condensate reaches a certain level.

Can automatic drain valves waste compressed air?

Timer-based drains can waste air if not adjusted correctly. Zero-loss drain valves are designed to release only water, preventing compressed air loss.

Where should an automatic drain valve be installed?

Auto drain valves should be installed at the lowest level of the setup, like tanks, storage tanks, and air receivers, where condensate naturally collects.

Do automatic drain valves require regular maintenance?

Yes. Periodic inspection is required to check for clogging, sensor function, and proper drainage. Regular maintenance ensures reliable operation and long service life.

Are automatic drain valves suitable for high-pressure setups?

Most auto drain valves are designed for industrial pressure ranges. Always verify the valve’s maximum pressure rating before installation.

What causes an automatic drain valve to stop working?

Common causes include clogging from contamination, faulty sensors or timers, improper installation, or worn internal components.

Is a zero-loss drain valve worth the higher cost?

Yes, for setups with continuous operation or high energy costs. Zero-loss drain valves eliminate air loss, improving long-term efficiency and reducing operating expenses.

Can one automatic drain valve handle the entire compressed air setup?

No. Large setups usually require multiple drain valves installed at different low points to ensure complete condensate removal.

Automatic drain valves are important for controlling water in compressed air systems where condensate formation is unavoidable. When properly selected and maintained, they safely remove gallons of accumulated condensate, protecting equipment from corrosion, improving air quality, and reducing the risk of unexpected collapse. A well-matched automatic drain solution supports long-term reliability while minimizing maintenance effort and operating costs.

Experience reliable moisture control with GiantAir automatic drain solutions. Our engineered drain valves ensure efficient condensate removal, reduced air loss, and long-term compressed air systems protection. Connect with the GiantAir team today and request our product catalog to select the right automatic drain valve for your air compressor.