Installing an air compressor correctly is very important. A good installation helps the system work well for a long time. It gives reliable air, runs efficiently, and avoids common problems. These problems include air leaks, pressure drops, excess heat, and damage to parts. A properly installed system also saves money on energy and maintenance.

This guide explains all the key steps to install a new air compressor safely. Following these steps helps the system run efficiently and reliably.

Pre-Installation Planning

Air Demand Assessment and Compressor Selection

Before starting installation, evaluate how the compressed air system will be used. Determine airflow demand, pressure requirements, and air quality needs for all air outlets and equipment.

Selecting the right type of compressor is critical; rotary screw compressors are commonly used in industrial air environments because they provide continuous airflow and handle high duty cycles.

Most rotary screw compressors are designed for steady operation, making them suitable for facilities with constant compressed air demand.

Compressor size should be matched to actual usage, not just peak estimates, and should account for noise levels, routine maintenance, and whether more than one compressor will be required.

Efficiency factors, such as cooling method, variable speed operation, and ambient conditions, should also be reviewed. Proper planning at this stage helps prevent oversizing, reduces energy waste, and ensures reliable operation.

Site Conditions

Site conditions directly impact compressor performance and long-term reliability. The installation area should be evaluated for ambient temperature, humidity, and overall ambient conditions before placing the compressor. To accommodate varying ambient temperatures worldwide, GiantAir offers air compressors with multiple operating temperature configurations for stable and efficient operation.

Most manufacturers recommend operating within a defined temperature range, as temperature extremes, excess heat, or poor airflow can shorten equipment life and affect internal components.

The compressor should not be exposed to direct sunlight, including afternoon sun, which can raise operating temperatures and introduce hot air into the air inlet.

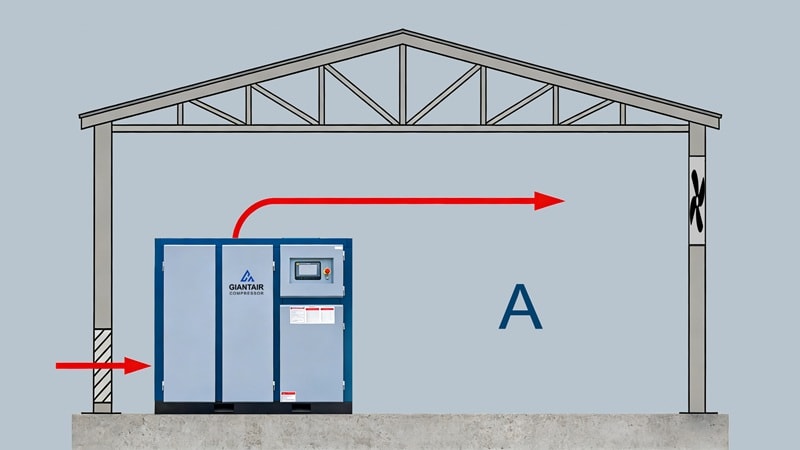

Adequate ventilation is required to remove heat and maintain proper airflow, especially in enclosed spaces.

Electrical infrastructure must also be verified at this stage. Confirm that the main electric service, power source, and available electrical outlets can support the compressor’s amperage rating and correct voltage.

Electrical and Safety Preparation

Before installation, take these steps:

- Verify voltage, phase, and amperage are correct for the compressor.

- Connect the compressor to a dedicated circuit with a proper breaker.

- Make sure it is grounded according to local electrical codes.

- Confirm all safety measures, including disconnects and maintenance team coordination, are in place.

Proper electrical preparation prevents equipment damage, reduces downtime, and keeps personnel safe.

Compressor Room Design and Layout

Environment:The compressor room should be a dedicated space that is clean, dry, and protected from airborne contaminants.

Floor:The floor surface must be flat and level concrete to support the compressor’s base, static weight, and gross dead weight. Vibration isolation pads or other pliable material should be installed between the compressor and the floor to reduce noise levels and mechanical stress.

Maintenance space:Enough space and clearance must be provided around the compressor for proper airflow, routine maintenance, and safe access by maintenance teams.

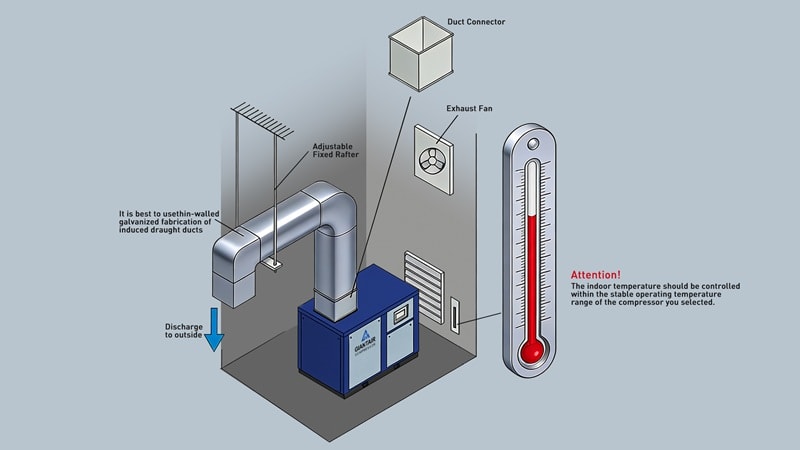

Ventilation:The ventilation system, which may include an exhaust fan or forced ventilation, is critical to remove hot air and prevent excess heat buildup. Lighting, electrical outlets, and a dedicated circuit should be planned as part of the room layout to support safe and efficient compressor operation.

- Louvered vents: For smaller air compressors, louvered air inlets and outlets in the compressor room may provide sufficient airflow to remove the heat generated during operation. However, the effectiveness of this approach depends heavily on ambient conditions such as room size, ventilation layout, and local climate. To ensure proper airflow and safe operating temperatures, it is recommended to consult a qualified HVAC professional for correct duct sizing, system design, and installation.

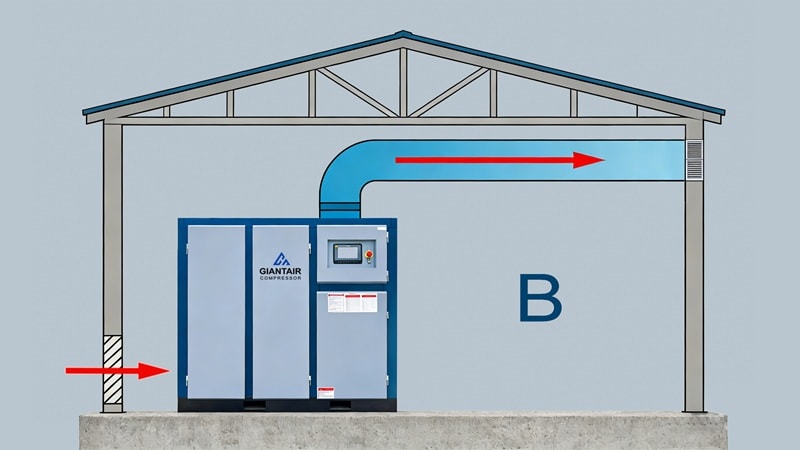

- Forced ventilation: Air compressors larger than 25 HP typically require forced ventilation, although the exact requirements vary by site. In these systems, an exhaust fan draws hot air through ductwork and discharges it outdoors. However, effective forced ventilation is often more complex than it appears—especially in small compressor rooms with low ceilings.

Duct design plays a critical role. Each bend, curve, or directional change increases airflow resistance and creates back pressure within the duct system. For example, a single 90-degree elbow can add resistance equivalent to approximately 30 feet of straight duct. When multiple bends are introduced to reach an outlet, airflow is significantly restricted, causing heat to accumulate inside the compressor enclosure and reducing cooling effectiveness.

Air Compressor Installation

Air compressor installation should always follow the manufacturer’s instructions and guidelines to ensure safe operation and protect the compressor system.

- Place the compressor on a level surface with full base support.

- Connect the air inlet and outlet with high-quality fittings and Teflon tape. This prevents leaks and ensures proper airflow.

- Install and secure the electrical cabinet, verifying the unit is properly grounded and that the electrical service voltage matches the compressor nameplate.

- Add compressor oil if needed. Follow the manufacturer’s guidelines. Inspect the entire unit before startup.

These steps make sure the compressor is used safely. Proper installation also extends the life of the compressor. A well-maintained, properly installed compressor can operate for many years without interruption.

Air Quality Management and Temperature

Air quality and temperature control are critical. Keep ambient temperature within limits. Too hot or too cold air reduces efficiency and wears parts faster.

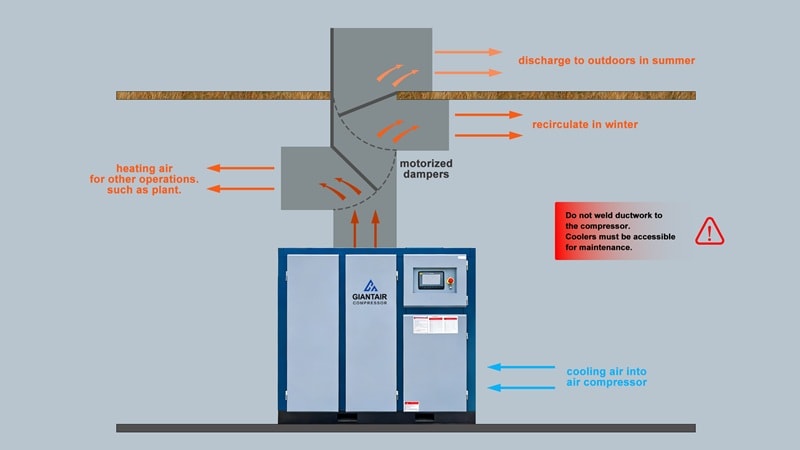

Heat recovery: In cold climates, waste heat from compressed air systems can be reused. Damper-controlled airflow can exhaust heat outdoors in summer. In winter, recovered heat can warm buildings or support other processes.

Poor ventilation allows hot air to flow back into the compressor. This increases wear on internal components.

Air filters should be installed and maintained. Use inlet filters, pre-filters, and after-filters as needed. Clean them regularly. This prevents airflow restriction and performance loss.

Regular cleaning and routine maintenance of air filters help prevent airflow restriction and performance loss.

Moisture control is equally important. A water separator and compressed air dryers should be installed to remove moisture from the air.

For applications such as painting, paint spray filter outlets can be added to protect equipment and product quality.

Monitoring air quality and maintaining proper airflow helps extend compressor life and supports consistent system performance.

Air Piping Installation

Proper installation of air compressor lines is essential for efficient compressed air delivery.

- Install the main pipeline with a slope of 1°–2° to allow condensed water to flow toward drain points.

- Use high-quality piping materials and fittings to prevent air leaks.

- Seal all joints carefully, using Teflon tape where appropriate.

- Consider receiver tanks. They stabilize pressure, reduce cycling, and support multiple compressors.

- Add a pressure regulator if required to control downstream pressure and protect equipment.

Good piping layout ensures steady airflow and reliable operation across the system.

System Testing and Startup

Before starting the compressor, check everything carefully. Make sure all connections are tight and air lines are correctly sized.

Check the power source and electrical panel to confirm voltage matches the compressor nameplate.

Start the compressor with no load. Listen for unusual noises. Gradually apply load while watching airflow, pressure, and temperature.

Check air quality. Make sure filters, air dryers, and water separators are working. Record baseline data for pressure, flow, and power. This helps with future maintenance.

Conclusion and Final Check

After installation and startup, do a final inspection. Confirm the system meets all local codes and safety standards. Ensure all connections are secure. Confirm the compressor is properly grounded. Check that voltage matches the nameplate.

Test the compressor under load. Watch airflow, pressure, and temperature. Record test results, maintenance, and repairs for future reference. Train maintenance staff on safety. Keep the compressor room clean and organized.

Proper installation prevents air leaks, reduces downtime, and extends compressor life. Installation takes time, but it is worth it. Following these steps keeps equipment safe and reliable. For more information about air compressor options, maintenance, and installation, contact us here!

FAQ

Why is proper air compressor installation important?

Proper installation helps the compressor work correctly. It prevents leaks, overheating, and damage. A well-installed system lasts longer and costs less to operate.

How do I choose the right air compressor?

Pick a compressor that meets your airflow and pressure needs. Some jobs need machines that can run all day. The right size keeps the system efficient and prevents wasted energy.

What are the most common installation mistakes to avoid?

Common mistakes include wrong electrical power, poor ventilation, and not leaving enough space around the compressor. Small air lines can reduce pressure. These mistakes often cause breakdowns and downtime.

Why is air quality management important?

Dirty air and moisture can damage equipment. Filters and dryers remove dirt and water. Clean air keeps tools and equipment running properly.

How often should an air compressor system be inspected?

Check the system after installation, then inspect regularly. Watch pressure and listen for unusual sounds. Keep records to help maintain long-term performance.