All-in-one Screw Air Compressor with Tank and Air Dyer | Save 70% Floor & Power

PRODUCT FEATURES

■ Fast and convenient, comes with gas storage tank, cold dryer, filter, no need to connect any pipelines to provide you with clean compressed air;

■ Space-saving and compact compressor system;

■ Durable, efficient and stable air end

■ Integrated cooler integrates oil cooling and after cooling;

■ Cyclone internal and external oil separator barrel design to reduce air oil content;

■ Winding oil separator design, low-pressure loss, long life, reduce your maintenance cost;

■ IE3 motor, save your electricity cost;

■ IP54, Class B temperature rise motor is suitable for harsh environments such as with bad dust and high temperature;

■ Permanent lubrication of the front and rear bearings of the motor;

■ High-temperature shutdown protection;

■ Motor overload protection;

■ Overpressure safety decompression system;

■ Optimize the shock-absorbing pad to reduce vibration and noise;

■ Place electrical components and oil separator and filtration modules that are easily damaged by high temperature in the cold room, which improves the service life of the unit.

Durable, efficient and stable air end

1. The design idea of "large rotor, large bearing, low speed" is adopted to reduce noise and vibration and increase the life and stability of the host.

2. The tooth surface is processed by the German KAPP rotor grinder to create a high-precision rotor, which is the first guarantee of high efficiency and stability of the air end.

3. Adopt a new type of 5: 6 asymmetric rotor tooth shape, high-precision three-coordinate measuring machine for comprehensive measurement, increase the air capacity by 5% -10%

4. All imported quality bearings are used.

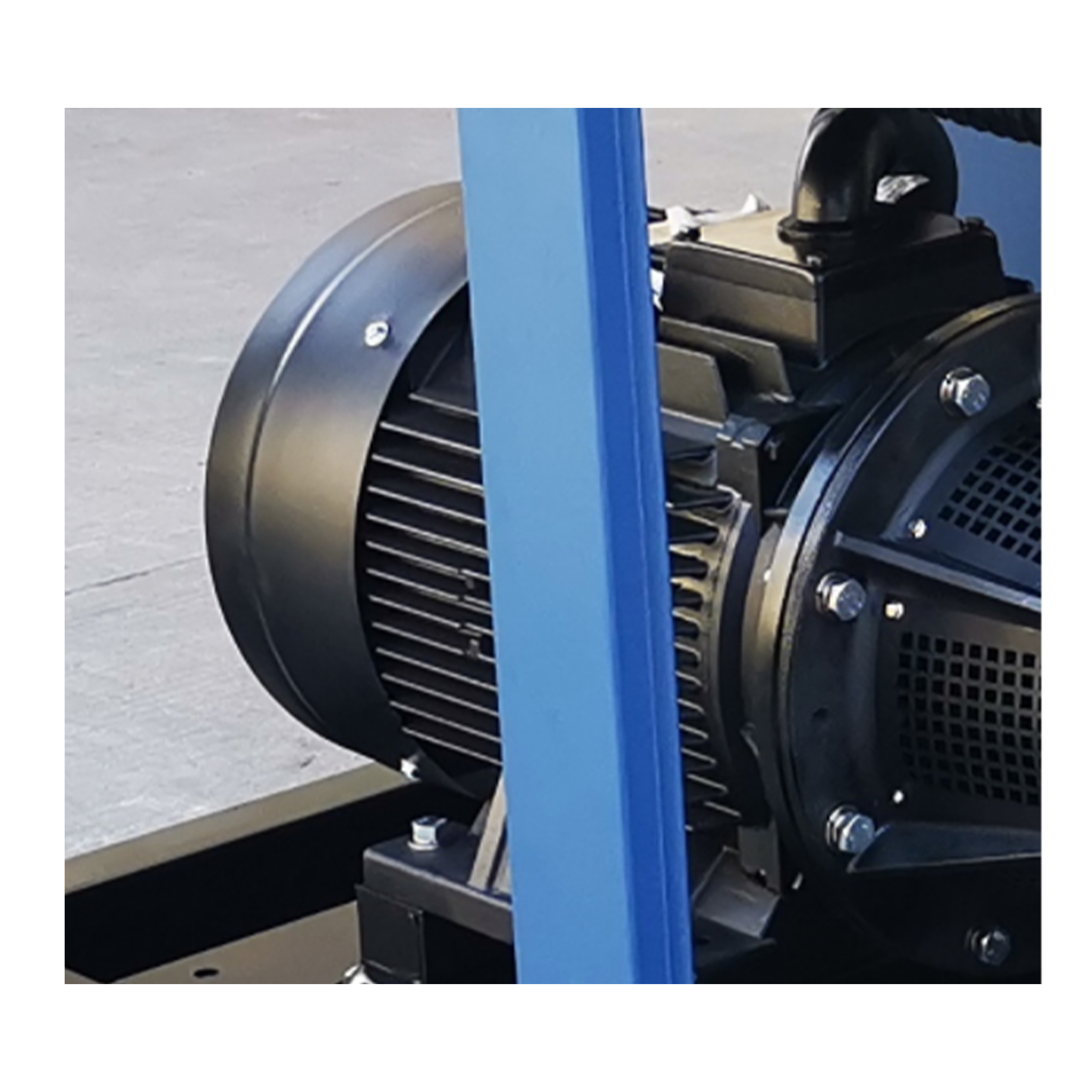

Specialized motor for air compressor

1. Large starting torque

2. Specialized motor for air compressor, imported quality bearings;

3. IE3 high energy efficiency motor, reduce your using cost

4. Motor design is designed according to 1.2 coefficient;

5. Protection grade IP54, insulation grade F.

6. Permanent lubrication of the front and rear bearings of the motor without adding grease

Permanent magnetic synchronous motor

1. IP65 protection level, more stable and reliable than IP23 in harsh environments;

2. Oil-cooled design, use lubricating oil to cool the motor, the operating temperature of the motor is more stable, the life is longer, there is no motor axial fan, so there is no loss of energy efficiency of the axial fan;

3. Coaxial design with the main rotor of the air end, without coupling, loss of energy efficiency of the gearbox;

4. Using 38UH magnetic steel material, temperature resistance 180 ℃

6. Permanent lubrication of the front and rear bearings of the motor without adding grease

Customized vector inverter

1. Professional customization, perfect match with motor;

2. Fully monitor the parameters of the motor, including the motor temperature, to reduce the risk of the high temperature of the motor;

3. Independent air duct design, strong environmental adaptability;

4. Quick response, the response time is less than 50mS

5. Large low frequency torque, can output 180% rated torque;

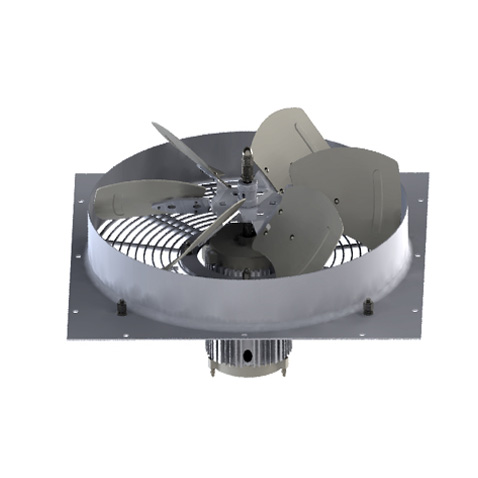

Inner rotor fan

1. IP44 cooling fan, Class F insulation;

2. Compared with the outer rotor fan, the inner rotor fan has higher air pressure, more air volume, and better cooling effect;

3. Due to high wind pressure, the cooler and filter are less likely to be blocked

Three filters

Air filter: the filter area exceeds 150% of the normal requirement, low the inlet pressure loss , and high energy efficiency ;

Oil filter: The design of the imported oil filter with enlarged glass fiber material is adopted. The rated processing capacity of the oil filter is ≥1.3 times of the circulating oil volume. The filtering accuracy is high and the durability is good.

Oil separator: imported glass fiber material oil core, good filtration effect, low oil core pressure loss.

Inlet valve

Inlet valve: low flow speed test, low pressure loss, reduce energy consumption;

Minimum pressure check valve: low pressure loss, precise control, ultra-fast repositioning to ensure that the user's air does not return.

Temperature control valve: Mixed flow temperature control valve: The unit is equipped with a mixed flow temperature control valve to ensure that the unit is more convenient to start in a low temperature environment, and to ensure the unit is in the best performance state by controlling the oil supply temperature of the air end

High temperature refrigerated air dryer

Reverse reflux heat exchange method is adopted, which is more energy-saving and stable than ordinary forward flow method;

Models above 13 bar use more efficient and high pressure resistant rustless steel plate heat exchangers.

The air-liquid separation efficiency reaches more than 99%;

The pressure dew point can be as low as 3 ℃

Inlet air temperature can be as high as 80 ℃

Filters

The piston-type filter core is sealed with the housing to prevent unfiltered air from bypassing the filter;

The new rectangular mixed fiber medium has a large effective area, improves the filtration rate, has a large open area, and minimizes pressure drop

The film-coated closed foam sleeve is resistant to oil and acid corrosion and prevents coalescing liquid from re-mixing into the airflow

Models above 13bar with differential pressure display;

Automatic drain valve

The electronic automatic drain valve is more stable than the floating ball automatic drain valve and is not easy to block (the floating ball automatic drain valve is very easy to block due to the problem of the drain hole)

Why Choose All-in-one Type Air Compressor?

GATD series screw compressor with tank includes screw compressor, air storage tank and other components in one

• After the air is integrated into the system, it can meet the process needs of various enterprises

• Space saving, compact compressed air system

• Complete system, no additional air tank, no connecting piping installation cost

• Easy to use, flexible and lightweight, users can use high-quality compressed air after connecting to the power supply

• Intelligent control system, imported Siemens Electric truly realizes intelligent operation

• It can be installed in the supporting production line modularly to improve the integrity of the production system

• The combination machine is an ideal choice for relatively quiet places such as small processing workshops, laboratories, and automobile 4S shops.

• Beautiful appearance, reliable performance, superior economy, exported to overseas

TECHNICAL PARAMETERS FOR ALL-IN-ONE SCREW AIR COMPRESSOR

| MODEL | MAXIMUM WORKING PRESSURE | FREE AIR DELIVERY* OF UNIT AT WORKING PRESSURE | MOTOR | TANK | NOISE LEVEL** | AIR OUTLET DISCHARGE SIZE | WEIGHT | DIMENSIONS | ||||

| Bar | PSI | l/s | m3/min | CFM | kW | HP | L | dBA | KG | L X W X H (mm) |

||

| GATD-10PM | 8 | 116 | 18 | 1.10 | 39 | 7.5 | 10 | 300 | 65±2 | G3/4 | 380 | 1710*730*1590 |

| 10 | 145 | 15 | 0.90 | 32 | ||||||||

| GATD-15PM | 8 | 116 | 28 | 1.70 | 61 | 11 | 15 | 400 | 65±2 | G3/4 | 520 | 1710*810*1720 |

| 10 | 145 | 27 | 1.60 | 57 | ||||||||

| GATD-20PM | 8 | 116 | 38 | 2.30 | 82 | 15 | 20 | 400 | 66±2 | G3/4 | 530 | 1710*810*1720 |

| 10 | 145 | 33 | 2.00 | 71 | ||||||||

| GATD-30PM | 8 | 116 | 57 | 3.40 | 121 | 22 | 30 | 500 | 66±2 | G1 | 650 | 1900*970*1840 |

| 10 | 145 | 53 | 3.20 | 114 | ||||||||

| ** Noise level operation at maximum operating pressure and maximum speed. Tested per ISO 2151 and the basic standard ISO 9614-2. | ||||||||||||

| Specifications are subject to change without notice. | ||||||||||||