High Flow 30hp-350hp 10Bar Low Noisy Direct Driven Industrial Two Stage Screw Air Compressor

PRODUCT FEATURES

1.latest high-tech screw air end, ensure high stability.

2.smoother cutting and better-looking cutting surface.

3.Multiple high-efficiency oil and water removaldevices ensure the compressed air entering the lasercutting machine is dry and oil-less

4.Thermostatic control minimizes the moisture contentof the air, ensuring system reliability and lifetime.

5.Equipped with a large capacity air storage tank, whichstabilizes the air supply pressure and condensates the moisture.

6.The integrated automatic drainage system improvesthe purity and dryness of the compressed air, significantlykeeps the laser lens clean away from contamination.

7.All-in-one design, user-friendly, easy to use and transport

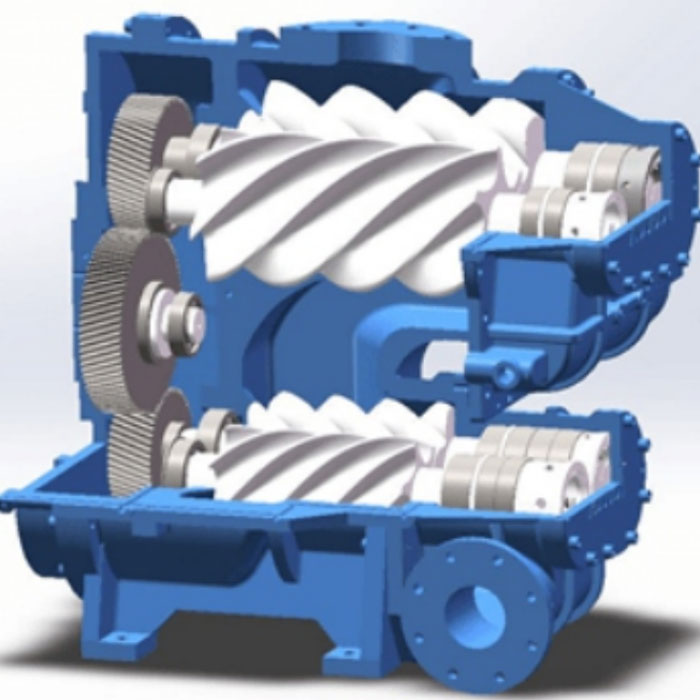

Product Image

First stage compression unit and the second stage compression unit are integrated in one air end driven directly by the helical gear, the optimal linear speed for each stage. After the first stage compression, constant pressure compression by intensify spread oil cooling, reduce the second stage compression suction temperature, ensure that the second stage compression unit is close to isothermal compression. Compression ratio reasonable distribution, optimized bearing design, second stage compression reduces the compression ratio of each stage, reduces internal leakage, improves the volume efficiency, reduces the bearing load, and improves the life of the air end. In the same power, double stage compression energy saving is 15% more than the single stage compression.

TECHNICAL PARAMETERS FOR TWO STAGE SCREW AIR COMPRESSOR

|

MODEL |

MAXIMUM WORKING PRESSURE |

FREE AIR DELIVERY* OF UNIT AT WORKING PRESSURE |

MOTOR |

NOISE LEVEL** |

AIR OUTLET DISCHARGE SIZE |

WEIGHT |

DIMENSIONS |

||||

|

Bar |

PSI |

l/s |

m3/min |

CFM |

kW |

HP |

|

KG |

L X W X H |

||

|

GTS-30PM |

8 |

116 |

55 |

3.30 |

118 |

22 |

30 |

72±3 |

G1 |

630 |

300 x 900 x |

|

10 |

145 |

48 |

2.90 |

104 |

|||||||

|

13 |

189 |

35 |

2.10 |

75 |

|||||||

|

GTS-40PM |

8 |

116 |

78 |

4.70 |

168 |

30 |

40 |

72±3 |

G1 1/2 |

800 |

1580 x 1080 x |

|

10 |

145 |

72 |

4.30 |

154 |

|||||||

|

13 |

189 |

58 |

3.50 |

125 |

|||||||

|

GTS-50PM |

8 |

116 |

103 |

6.20 |

221 |

37 |

50 |

72±3 |

G1 1/2 |

870 |

1580 x 1080 x |

|

10 |

145 |

87 |

5.20 |

186 |

|||||||

|

13 |

189 |

73 |

4.40 |

157 |

|||||||

|

GTS-60PM |

8 |

116 |

108 |

6.50 |

232 |

45 |

60 |

72±3 |

G1 1/2 |

950 |

1580 x 1080 x |

|

10 |

145 |

87 |

5.20 |

186 |

|||||||

|

13 |

189 |

75 |

4.50 |

161 |

|||||||

|

GTS-75PM |

8 |

116 |

162 |

9.70 |

346 |

55 |

75 |

75±3 |

G2 |

1550 |

1800 x 1400 x |

|

10 |

145 |

123 |

7.40 |

264 |

|||||||

|

13 |

189 |

107 |

6.40 |

229 |

|||||||

|

GTS-100PM |

8 |

116 |

210 |

12.60 |

450 |

75 |

100 |

75±3 |

G2 |

1668 |

1800 x 1400 x |

|

10 |

145 |

183 |

11.00 |

393 |

|||||||

|

13 |

189 |

157 |

9.40 |

336 |

|||||||

|

GTS-125PM |

8 |

116 |

258 |

15.50 |

554 |

90 |

125 |

75±3 |

G2 |

2480 |

2000 x 1540 x |

|

10 |

145 |

208 |

12.50 |

446 |

|||||||

|

13 |

189 |

183 |

11.00 |

393 |

|||||||

|

GTS-150PM |

8 |

116 |

325 |

19.50 |

696 |

110 |

150 |

83±3 |

DN65 |

2570 |

3000 x 1550 x |

|

10 |

145 |

267 |

16.00 |

571 |

|||||||

|

13 |

189 |

233 |

14.00 |

500 |

|||||||

|

GTS-175PM |

8 |

116 |

372 |

22.30 |

796 |

132 |

175 |

83±3 |

DN65 |

2770 |

3000 x 1550 x |

|

10 |

145 |

325 |

19.50 |

696 |

|||||||

|

13 |

189 |

267 |

16.00 |

571 |

|||||||

|

GTS-250PM |

8 |

116 |

458 |

27.50 |

982 |

160 |

250 |

85±3 |

DN80 |

3120 |

3500 x 1900 x |

|

10 |

145 |

405 |

24.30 |

868 |

|||||||

|

13 |

189 |

367 |

22.00 |

786 |

|||||||

|

GTS-350PM |

8 |

116 |

700 |

42.00 |

1500 |

250 |

350 |

87±3 |

DN100 |

5600 |

3600 x 2000 x |

|

10 |

145 |

625 |

37.50 |

1339 |

|||||||

|

13 |

189 |

550 |

33.00 |

1179 |

|||||||