High Quality 3.8m3/Min Energy-Saving Twin Tower Heatless Compressed Air Adsorption Dryer For Industrial Air Compressor

Product Image

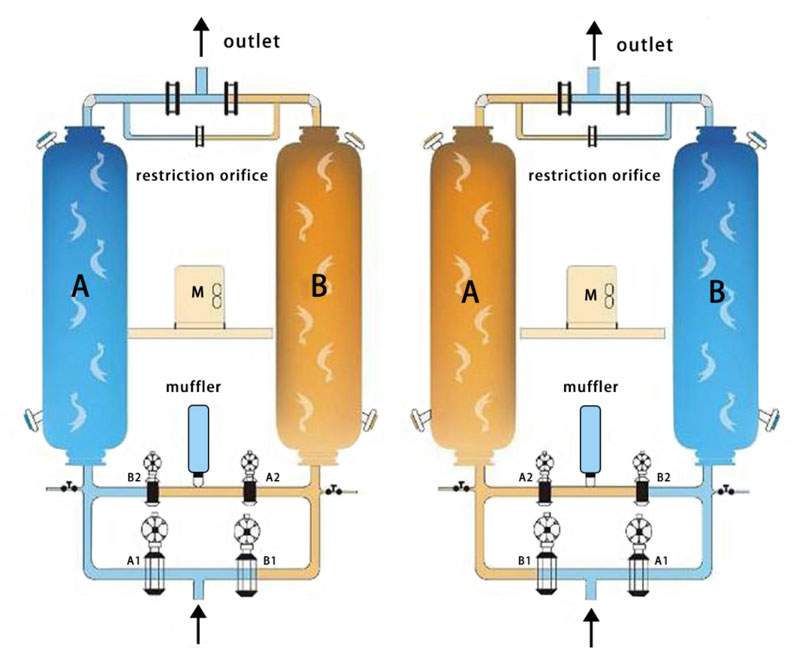

Type 1: Heatless Adsorption Dryer

How it works?

The heatless regenerative adsorption dryer is a kind of equipment for drying compressed air according to the principle of pressure swing. It absorbs the moisture in the compressed air under pressure to dry the compressed air, and uses a part of the dry compressed air during decompression. Purging the adsorbent to regenerate the adsorbent. The two towers are alternated with each other to obtain dry compressed air. Different adsorbents are selected according to the dew point of the compressed air pressure. The commonly used adsorbents are activated alumina and molecular sieves.

• Pressure Dew Point(PDP): -20~-40℃

• Capacity: 1.2~200m3/min(42~7142cfm)

• Working pressure: 6~10bar

• Inlet temperature: ≤38℃

• Purge air: ≤13%

• Inlet oil contain: ≤0.01ppm

• Adsorbent: Alumina, molecular sieving

• Power Supply:220v/50Hz

• Control Mode: Microcomputer Automatic Control

Type 2: Heated Adsorption Dryer

How it works?

Micro-heat regeneration adsorption dryer is an energy-saving and high-efficiency dryer. It is a product developed by absorbing the advantages of thermal regeneration and non-heat regeneration. The purging regeneration can save the regeneration air consumption, the regeneration effect is good, and the adsorption working time is longer.

Heater: high strength, high voltage resistance, electric shock resistance, good heating insulation

• Pressure Dew Point(PDP): -20~-40℃

• Capacity:1.2~200m3/min(42~7142cfm)

• Working pressure: 6~10bar

• Inlet temperature: ≤38℃

• Purge air: ≤7%

• Inlet oil contain: ≤0.01ppm

• Adsorbent: Alumina,molecular sieving

• Power Supply:220v/50Hz

• Control Mode: Microcomputer Automatic Control

Features

Product Parameter Table

|

TYPE |

CAPACITY |

ADSORBENT |

INLET |

DIMENSIONS(MM) |

WEIGHT(KG) |

MATCHED AIR |

||

|

LENGTH |

WIDTH |

HEIGHT |

||||||

|

AD-015 |

1.5 |

28 |

G-1 |

780 |

510 |

1600 |

185 |

7.5 |

|

AD-020 |

2 |

40 |

G-1 |

900 |

550 |

1600 |

209 |

11 |

|

AD-026 |

2.6 |

55 |

G-1 |

900 |

550 |

1320 |

270 |

15 |

|

AD-038 |

3.8 |

90 |

G1-1/4 |

900 |

550 |

1450 |

317 |

22 |

|

AD-069 |

6.9 |

155 |

G-1/2 |

1010 |

600 |

1820 |

398 |

37 |

|

AD-110 |

11 |

250 |

G2 |

1180 |

650 |

1950 |

482 |

55 |

|

AD-140 |

14 |

305 |

DN65 |

1085 |

940 |

2200 |

587 |

75 |

|

AD-180 |

18 |

345 |

DN65 |

1350 |

850 |

2200 |

745 |

90 |

|

AD-220 |

22 |

385 |

DN65 |

1230 |

1000 |

2200 |

895 |

110 |

|

AD-280 |

28 |

530 |

DN80 |

1410 |

1150 |

2250 |

1155 |

150 |

|

AD-320 |

32 |

645 |

DN80 |

1470 |

1310 |

2250 |

1207 |

160 |

|

AD-380 |

38 |

725 |

DN100 |

1470 |

1310 |

2360 |

1449 |

200 |

|

AD-460 |

46 |

910 |

DN100 |

1470 |

1310 |

2580 |

1652 |

250 |

|

AD-550 |

55 |

1080 |

DN125 |

1570 |

1550 |

2900 |

1816 |

315 |

|

AD-670 |

67 |

1200 |

DN150 |

1820 |

1630 |

2950 |

2325 |

355 |

|

AD-750 |

75 |

1320 |

DN150 |

2000 |

1700 |

2980 |

2750 |

400 |

|

AD-850 |

85 |

1500 |

DN150 |

2320 |

2150 |

3200 |

3125 |

450 |