Introduction to Air Compressors

Essential to modern industry, air compressors power everything from manufacturing lines to food packaging and medical systems.

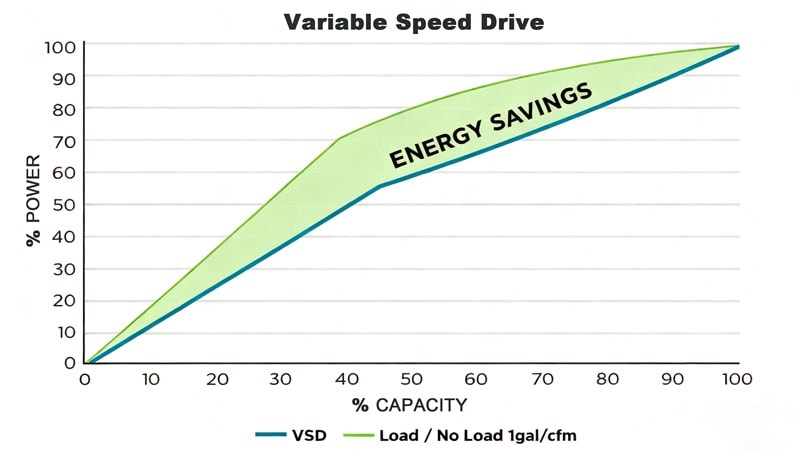

The compressed air system can account for as much as 30% of the total electricity use in many facilities, at least according to the United States Department of Energy. Boosting efficiency in this area can result in energy savings of up to 50%.

Consequently, air compressors can serve as a critical component for efficiency and cost control. So, why are air compressors so functional and efficient?

In this article, we take a look at how the compressed air application process can result in less power consumption while actively improving your system reliability.

Understanding Motor Speed and Variable Frequency Drive

To maximize the efficiency of your air compressor system, it’s important to understand the way that motor speed and variable frequency drive technology influence your experience.

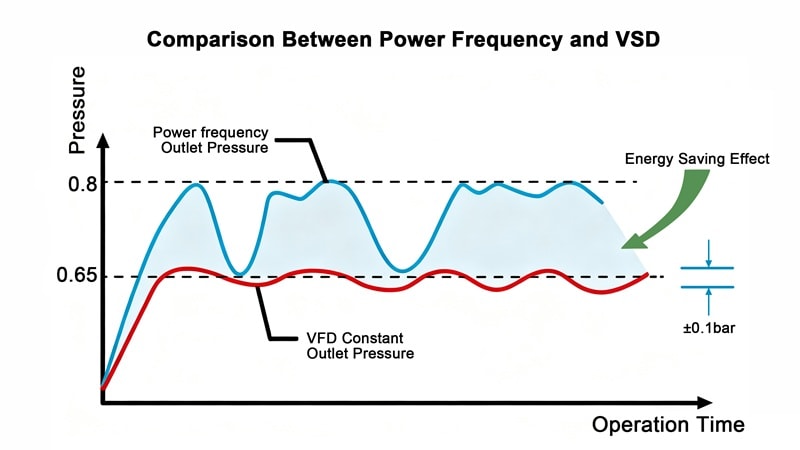

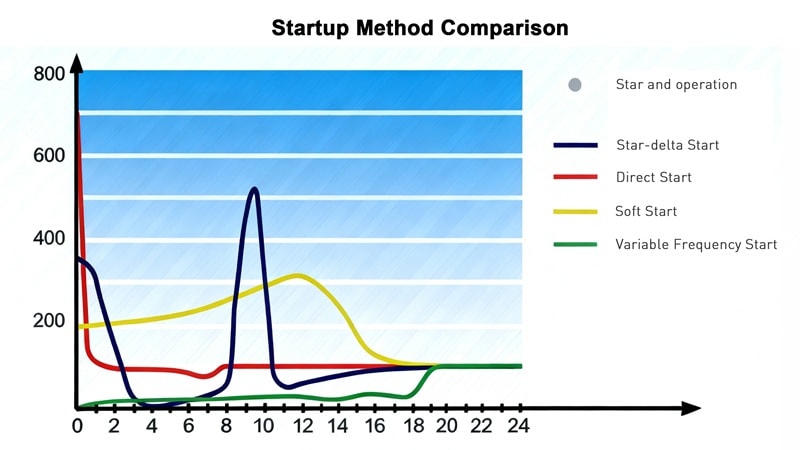

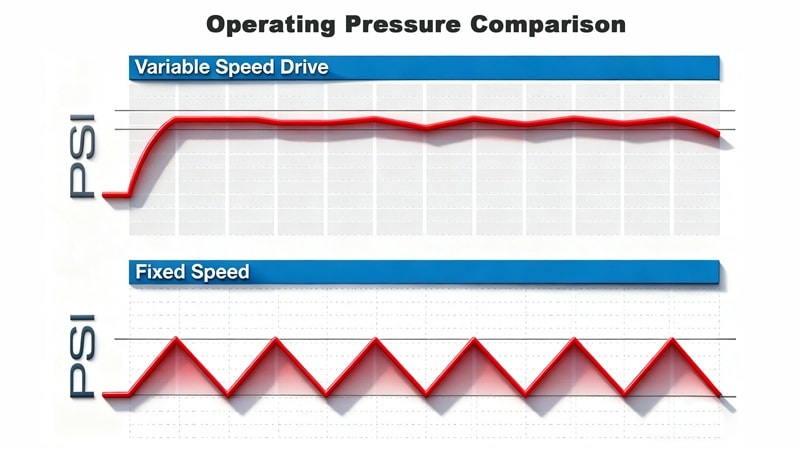

The amount of energy that a compressed air system consumes is directly tied to its motor speed. Fixed-speed compressors tend to use more energy than is required.

Essentially, they produce the same output regardless of what is actually needed. The compressed air output is unrelated to the actual demand whereas with a variable speed drive compressor, it is matched.

For fixed speed systems, the compressor’s motor speed can create a lot of unnecessary maintenance and energy consumption.

On the other hand, there is the VFD compressor.

A VFD compressor uses variable frequency drive technology to automate motor speed adjustments. Under this system, the facility’s output is catered to the air requirements.

For businesses, this means that your air compressor always gives you exactly what you need it to, but never more than is necessary.

It allows you to meet compressed air demand while optimizing for efficiency and reducing wear and tear.

Advantages include:

- Adjusting motor speed to match variable air demand in real time

- Reducing overall energy consumption and lowering power costs

- Decreasing mechanical stress for longer equipment life

- Maintaining consistent air pressure for sensitive applications

Over time, this process can result in considerable energy savings, making VFD technology the strategic choice for many companies.

Benefits of Variable Speed Drive (VSD) Technology

Variable speed drive technology is the preferred option for facilities where air demand fluctuates throughout the day. It’s function aligns with the fact that different jobs have different requirements.

Plants that have numerous shifts or different workloads need systems that don’t stress their budget or their equipment with unnecessary power draws.

A VSD air compressor minimizes the amount of energy being consumed and consequently extends the life of the equipment itself by eliminating unnecessary strain.

As a result, you get:

- Lower energy bills

- Less equipment maintenance

- The potential for energy efficiency–based tax incentives

It’s one of the easiest and most logical ways for a business to reduce its operational costs and lessen its environmental impact in one move.

How VSD Compressors Work

VFD compressors use sensors to monitor air conditions and match output based on need. Air pressure rises within the lines when air demand drops, a change that is detected by the system.

When this takes place, the motor begins to slow down. Energy consumption declines immediately, and less strain is placed on the system as a whole.

On the other hand, when demand increases and pressure falls, the motor begins to ramp up production again.

The VFD accomplishes this by:

- Adjusting frequency and voltage supplied to the motor

- Adjusting the motor’s rotational speed

- Producing exactly the amount of air needed at the moment

This serves as an affordable and efficient alternative to fixed-speed machines that create a constant start-stop cycle.

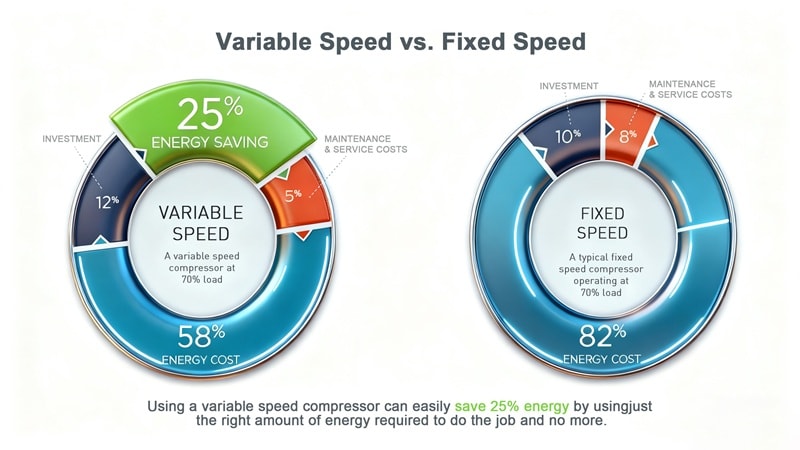

Energy Consumption and Savings

VSD systems generally cost more on the front end. However, with time, they are usually the least expensive option thanks to the savings that they provide.

It takes about 2–5 years to recoup the costs of a VSD compressor through energy savings, but the exact variation will depend on:

- Factory size

- Operating hours

- Baseline energy costs

That said, it’s important to consider the investment not just in short-term terms, but also in the total savings over the lifetime of ownership.

Reductions in energy costs can accumulate to thousands of dollars, while there is often a distinct maintenance advantage as well.

Because VFD compressors draw less power and cycle less frequently, they frequently reduce wear on components and lower replacement costs over time. The caveat is that these savings are really only realized in environments that put their compressed air system through heavy, regular use.

When a VSD/VFD Compressor Makes Sense

When demand remain consistent, you may be able to make due with a fixed speed unit. That said, in most given compressed air application scenarios, you will benefit from the efficient controls provided by VSD units.

VSD compressors ensure that you always have enough energy to meet your needs, while providing the most efficient controls available for your energy use needs. Full speed capacity when its needed, with less of a load on your energy consumption required when your varying performance needs shift.

Typically, customers in a wide variety of industries benefit from compressed air equipment that will provide significant energy savings in the form of a variable frequency drive VFD.

When a VSD/VFD Is Not Recommended

VSD compressors are great for saving energy, reducing maintenance costs, and generally matching output with need.

However, they are not necessarily suitable for every situation. Fixed-speed compressors can absolutely be the most practical and cost-effective choice depending on the requirements of your facility. VSD compressors are not recommended when:

- Air demand is extremely stable: If your demand is constant or at least close to it, you won’t really see energy savings from a VSD compressor. In this context, the additional costs of the equipment may not be recuperated in long-term savings.

- Initial budget is highly constrained: It is true that VSDs will save you money in the context of lifetime ownership, but businesses with a restrained early budget may not be able to justify or manage the higher upfront costs. VSDs are in this way prohibitive for smaller operations in certain cases.

- Environmental conditions are challenging: Not every working environment is suitable for VSD compressors. If the ambient temperatures are either very high or very low, VSD technology will not be reliable. The same is true for environments that become very dusty or otherwise contaminated.

There are other factors that can make fixed-speed units better suited to your needs:

- Short duration: If you’re only operating for a few hours at a time, a fixed-speed unit may make the most sense, even if your power draw requirements do fluctuate. If you’re not getting enough service time, the cost-to-benefit analysis may not be proportionate to your needs.

- Simple small-scale systems: Similarly, simple operations may not adequately benefit from the complexity of a VSD system.

- Limited maintenance resources: While VSD systems are lower maintenance in the long run, they do require different maintenance considerations that not every manufacturer will be prepared to match.

It really comes down to matching your needs with the right equipment. VSD systems do have many advantages, but they should be weighed against the full picture of your operations. If you are unsure how a VSD system would work for you, consider speaking with a sales team.

They will be able to provide custom recommendations based on your specific requirements.

Applications of VFD Air Compressors

Versatile and able to be applied to many different situations, VFD compressors are the best choice for a wide range of industries where efficiency is a priority.

Common applications include manufacturing and assembly. By providing reliable air production for lines and pneumatic tools, and robotic systems, VFDs can be an excellent way to reduce energy costs in manufacturing and assembly environments.

- Automotive industry: VFD compressors are a common option for body shops, assembly lines, automotive painting facilities, and testing environments.

- Electronic and precision industries: VFD compression is ideal in environments that require a level of sensitivity or restrictive regulatory considerations. Because the operation is so precise and smooth, it is able to conform easily to industry requirements.

Other sectors that benefit from VFD technology include:

- Food and Beverage: VFD compressors are a common component of food and beverage packaging lines where pressure requirements can fluctuate based on the products being packaged.

- Mining and heavy industry: Mining and other heavy industry activities often require variable air outputs. VFD systems are able to match the industry’s needs without wasting energy.

Ultimately, nearly any facility can potentially benefit from a VFD system, provided that it operates frequently enough to actually receive the cost benefit.

Seasonal facilities or manufacturing environments with multiple shifts are also good examples of places that would receive an operational advantage. The more variation and use at work in your compressed air system, the more likely it is that you will benefit from VFD.

FAQ

What is a VFD air compressor?

A VFD (Variable Frequency Drive) air compressor automatically adjusts motor speed based on real-time air demand, producing exactly the amount of compressed air needed at any moment.

Is a VFD compressor really worth it?

Yes, for facilities with fluctuating air demand and regular heavy use, though fixed-speed units work better for operations with stable, constant demand.

How much can a VFD air compressor save?

VFD compressors can reduce energy consumption by up to 50%, with savings accumulating to thousands of dollars over the equipment’s lifetime.

Can a VFD replace a fixed-speed compressor?

Yes, VFD compressors can replace fixed-speed units in most applications, especially where air demand varies throughout the day.

What industries benefit most from VSD compressors?

Manufacturing, automotive, food and beverage, electronics, and mining industries benefit most due to their variable air pressure requirements.

How long does it take to recover the cost of a VSD compressor?

The typical payback period is 2–5 years through energy savings, depending on facility size, operating hours, and baseline energy costs.

How much power does a VFD compressor save?

VFD compressors can save up to 50% on energy consumption by matching output to actual demand rather than running at constant speed.

How to choose the right VFD compressor size?

Contact a sales team for recommendations based on your peak air demand, operating patterns, and pressure requirements to ensure proper sizing.

Conclusion

Through greater efficiency, lower maintenance costs, and a generally enhanced experience of reliability, VFD air compressors are the most natural choice for a wide range of businesses. Not only will they save you money, but they will also likely result in less time lost to maintenance and repairs. It is difficult to even put a price on the value of reliability in the industrial setting.

You’ll likely find that, given enough time, the math will strongly favor VFD compression in most cases.

Discover how GiantAir VFD compressors can cut costs, enhance system reliability, and provide long-term operational value. Contact us today and download our catalog to learn more or to request a consultation.