As the fourth most widely used energy source in the industrial field, the air compressor system is closely related to production. In addition, the air compressor system itself consumes a lot of energy due to its cluster control requirements and energy consumption management needs. In response to the trend of governments around the world actively promoting energy conservation and sustainable development, many energy-saving and efficiency improvement technologies have been applied to air compressors to reduce energy waste.

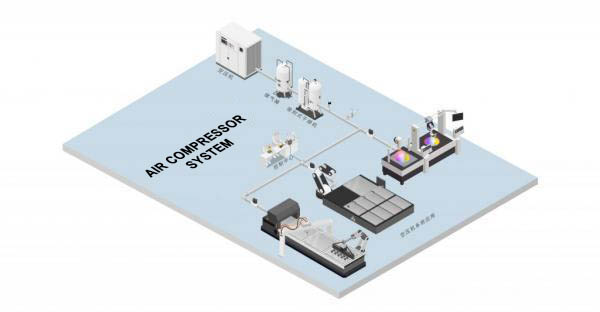

The air compression system refers to an energy conversion system that compresses the air in the atmosphere through a compressor and then transports it to the place where it is needed through a pipeline. The principle is to compress the gas in the low-pressure atmosphere into high-pressure air through rotation or reciprocating motion, and then transport it to the place where it is needed through a pipeline. The air intake filter can filter out impurities and dust in the air, so that the air intake of the compressor can obtain clean air, thereby ensuring the quality of the air. The cooler can dissipate the heat generated by the compressor during operation, thereby avoiding overheating of the machine. The oil separator can separate the oil vapor and liquid oil discharged by the compressor to ensure the purity of the air. The air storage tank is used to store the air compressed by the compressor so that it can be supplied to the user when needed. The air distribution pipeline transports the air in the air storage tank to the required air power equipment. Pneumatic components include cylinders, pneumatic actuators, pneumatic regulating components, etc., which can convert the high-pressure air output by the compressor into mechanical energy.

In the pipeline gas supply system, the most basic control object is flow rate, and the basic task of the gas supply system is to meet the user’s demand for flow rate. There is a certain relationship between the instantaneous flow rate and gas production of the air compressor. Generally speaking, the larger the instantaneous flow rate, the greater the gas production. This is because the more air volume discharged by the air compressor in a given time, the larger the volume of compressed air produced. However, it should be noted that the instantaneous flow rate and gas production are not a one-to-one correspondence, and are also affected by the operating state and load conditions of the air compressor. At present, the common gas flow control methods include loading and unloading gas supply control methods and speed control methods. However, since the air compressor cannot rule out the possibility of long-term operation under full load, the current at the time of starting is still very large, which will affect the stability of the power grid and the safe operation of other electrical equipment, and most of them are continuous operation. Since the drag motor of the general air compressor itself cannot adjust the speed, it is not possible to directly use the change of pressure or flow rate to achieve the matching of speed reduction adjustment output power. The motor is not allowed to start frequently, resulting in the motor still running at no load when the gas consumption is small, and huge waste of electric energy.

Moreover, frequent unloading and loading cause the pressure of the entire gas network to change frequently, and it is impossible to maintain a constant working pressure to extend the service life of the compressor. Some air compressor adjustment methods (such as adjusting valves or adjusting unloading, etc.) even when the required flow rate is small, because the motor speed remains unchanged, the motor power decreases relatively little. For this reason, for flow monitoring in the air compressor pipeline supply system, Gongcai.com recommends Siargo Sixiang Insertion Mass Flow Meter – MFI, American Siargo MF5900 series gas mass flow meter.

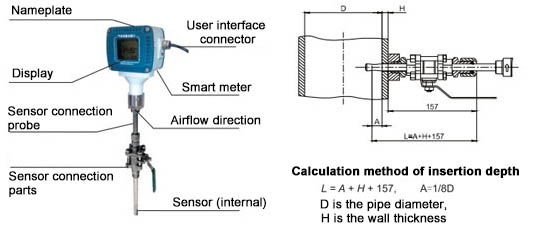

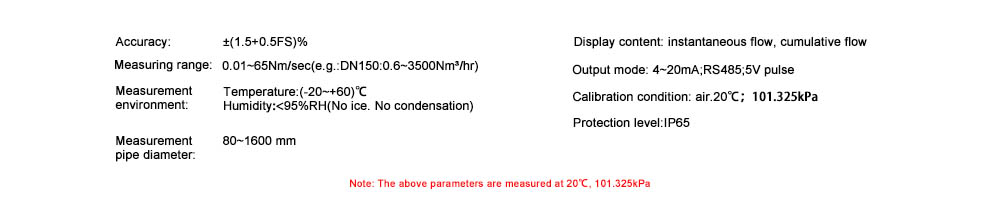

Siargo Insertion Mass Flow Meter – MFI is designed for gas monitoring and control of large pipelines. Online installation will not be difficult and more economical. The insertion mass flow meter is equipped with a self-sealing valve, which provides customers with an effective solution to gas measurement with minimal interference. It is recommended to use it on pipelines with a diameter of ≥150mm. The accuracy of all insertion mass flow meters is ± (1.5 + 0.5FS)%, and can reach higher standards according to customer needs. The working environment temperature of this product is -20—+60C, and the working pressure is 1.5MPa. This product can also be used for gas measurement and control in the production process, such as monitoring and control of oxygen, nitrogen, helium, argon, compressed air and other gases. In addition, it can also be widely used in other fields.

MFI Series Insertion Mass Flow Meter Product Parameters

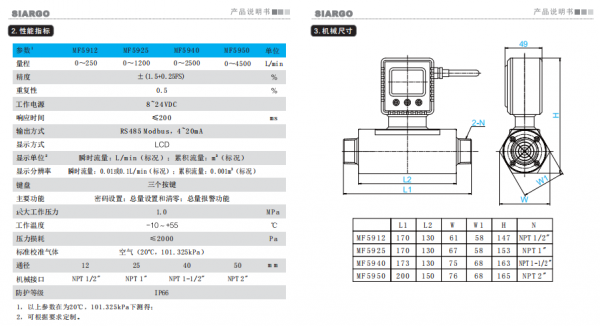

Siargo Flow Sensor – MF5900 Series is a network-based meter developed based on our company’s self-developed MEMS flow sensor chip. This meter can be used for a variety of gas flow monitoring, measurement and control applications. MF5900 Series Gas Mass Flow Meter Reference Standard: IS014511; GB/T 20727-2006.

American Siargo flow sensor MF5900 series parameters:

Post time: Jun-04-2024