Rotary screw air compressors are the backbone of modern industrial operations. They deliver unmatched efficiency compared to piston compressors.

Manufacturers often cut their maintenance costs when they switch to screw compressor technology. We’ve seen this transformation firsthand across manufacturing facilities, automotive plants, and construction operations—the difference in uptime is dramatic.

In this article, we’ll look at screw compressor working principle, from the interlocking rotors to the compression cycle. We’ll also identify the components, the industries that they are applicable to, and how to maintain them for decades of reliable service.

Read on to learn more about one of the most dependable workhorses in the industrial landscape, and discover everything you need to know about the compression process.

What Is a Screw Compressor?

To put it simply, a rotary screw air compressor is a positive displacement machine. It uses two helical rotors to compress air continuously. The other most common option is a reciprocating piston compressor, which delivers air in pulses.

Screw compressors, by contrast, provide a much smoother and uninterrupted airflow. This makes them ideal for operations that cannot afford fluctuations in pressure.

To compare the two, a piston compressor is a little like a bicycle pump. Air is produced in short bursts.

Screw compressors, on the other hand, produce a steady stream of air more comparable to the output of a garden hose.

The compression method is what makes the difference. Piston compressors use a crankshaft and pistons, which move up and down to compress air in stages.

Through this method:

- Vibration

- Noise

- And a pulsating airflow are created

Rotary screw compressors, on the other hand, mesh two rotors to compress air.

One rotor a male, the other a female. They rotate in opposite directions, trapping air in the space between them to gradually compress it as the volume decreases.

Not only does this method deliver continuous operation, but it also:

- Reduces noise

- Increases the lifespan of the rotor

In a much more efficient model.

Piston compressors are sufficient in small workshop environments where airflow needs are intermittent.

However, for operations that require reliable compressed air for extended periods of time, nothing can outperform rotary screw air compression.

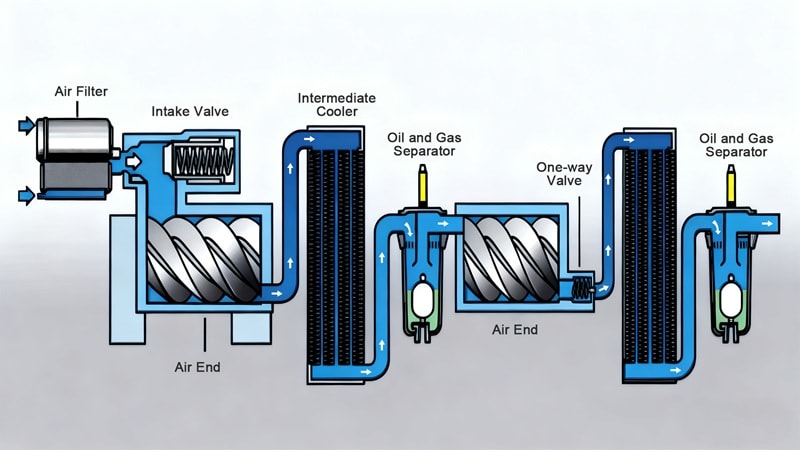

Types of Compressors

Not all rotary screw air compressors are the exact same. Your needs will depend on several factors:

- Your air quality requirements.

- Your pressure demands.

- And the specifics of your intended application.

It’s important to understand the subtle but impactful distinctions between compressor models.

Oil-Lubrication

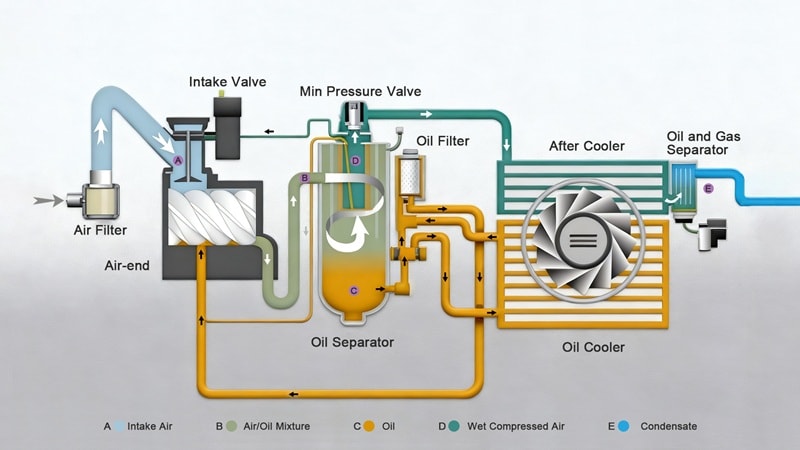

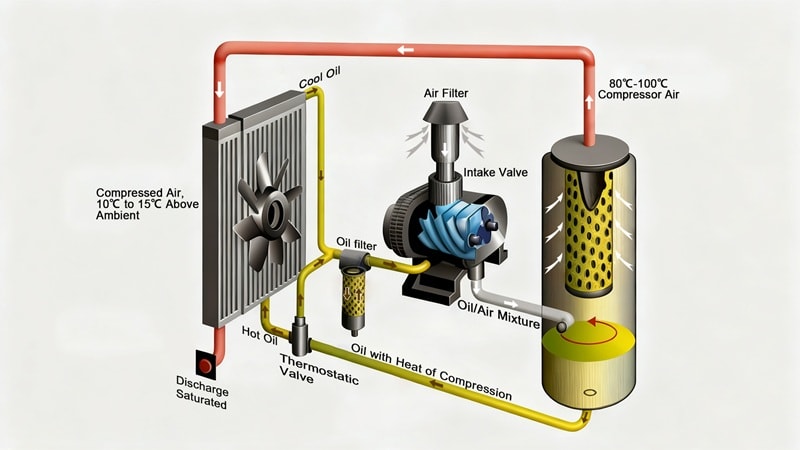

Oil-lubricated compressors use oil in the compression chamber. This seals gaps between rotors and reduces friction. It also helps to dissipate heat.

During the compression process, the oil gets mixed in with the air and then separates through an oil separator prior to delivery. These compressors are ideal in general industrial applications, noted for their higher air pressure ratios and their general reliability.

Oil-Free

On the other hand, there are also oil free screw compressors. With these machines, the rotors never actually make contact with one another. Instead, they are precision-engineered with tight tolerances. External gears synchronize them.

The compressed air is 100% clean and there is no risk of contamination from oil. This is the standard model for industrial environments where no level of contamination is acceptable.

For example:

Any industry in which even a small amount of oil is dangerous needs oil-free compression.

Twin/ Single Screw Type Air Compressors

Finally, there are twin screw air compressors. These units use two intermeshing helical rotors. The male rotor has lobes and the female rotor has grooves.

This is a common design in industrial settings. It can handle a high pressure ratio and large volumes.

There are also single screw compressors that use one central screw rotor with two gate motors positioned on either side.

Single screw air compressors are a one step method suitable for producing incoming air in smaller tasks.

While they are good at helping users achieve their desired pressure in minor applications their capacity control and energy efficiency are limited in industrial environments.

Which compression method is best? There is no objective answer to that question. It really just depends on finding the right compressor for your application.

While there are a wide range of numerous benefits to both oil injected and food grade units, success is all about choosing correctly from the various compressor types.

Specialized Compressors

There are also specialized compressors in the form of:

- Positive Displacement Compressors

- Centrifugal Compressors

- Rotary compressor

The many options reflect all of the possible use cases of compressed air.

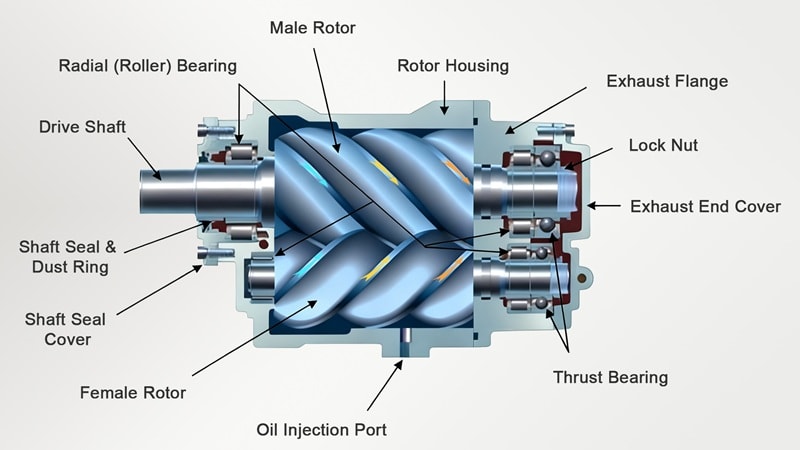

Components of a Rotary Screw Air Compressor

There are several key components of a rotary screw air compressor that will help you understand the way they work and the results that they produce.

The Inlet Valve

The inlet valve controls when ambient air enters the compression chamber. It opens to allow atmospheric air in. It closes to regulate flow based on demand.

The Compression Chamber

Then there is the compression chamber. This is where the male and female rotors are housed. It provides space for air to get compressed progressively.

In oil-lubricated compressors, it’s within this chamber that oil is injected. This seals gaps, cools the air, and also lubricates any moving parts.

The Rotors

Without question, the rotors are the soul of the system. There are two different kinds. The male rotor features protruding lobes.

These mesh with the grooves of the female rotor. As the rotors rotate in opposite directions, air gets trapped in the space between them.

As the rotors turn, the volume of these air pockets decreases. The air is compressed from atmospheric pressure (about 14.7 PSI—pounds per square inch) to your desired delivery pressure.

The Bearings

The rotors are supported by heavy-duty bearings. They can handle significant loads created during compression.

Filtration

Air passes first through an air filter before entering the compression chamber. The filter removes dust, dirt, and particulates.

In the case of oil-lubricated compressors, the oil-related contaminants are also removed as air circulates through the filter system.

This typically involves a two-stage process dependent on centrifugal force. Separated oil is then returned to the oil reservoir for further use.

The Outlet Valve

The outlet valve, or discharge port, meanwhile, releases hot compressed air from the system to the distribution lines. It’s through the outlet valve that compressed air circulates into it’s intended usage. The flow rate is often described in terms of cubic feet per minute.

The Housing

The compressor housing encases all of these components, providing structural support and acoustic insulation. As industrial equipment goes, it’s actually a very straightforward design, even if one that requires unwavering commitment to detail and precision.

Within the housing there are also smaller components including the:

- Solenoid valve

- Suction valve

- Slide valve

- Discharge valve

- Hydraulic seal

- Combustion chamber

- Exhaust port

- Timing gears

Through all of these elements, compressed gas can be cycled through the air end into its intended purpose.

Storage Tank

The storage tank maintains a constant supply of compressed air, allowing your air compressor to work without interruption.

How a Rotary Screw Air Compressor Works

Compression takes place in four continuous stages.

- First, the compressor starts, causing atmospheric air to rush through the inlet valve and into the compression chamber.

- From there, the rotating rotors create pockets that pull air in while the filter removes contamination.

- Then, the helical design reduces pocket volume, thereby increasing pressure from atmospheric levels up to 90-125 PSI or higher depending on your system requirements.

Once the air reaches its maximum compression, the outlet valve distributes it to your facility’s pneumatic tools, control systems, and manufacturing equipment.

Air compressors run on what is called a “duty cycle.” The duty cycle is listed as a percentage and describes the amount of downtime that a unit requires to avoid overheating.

A 75% duty cycle means that the compressor needs to rest for 2.5 of every ten minutes. There are industrial grade, energy efficient units that never need to rest.

Applications of Rotary Screw Air Compressors

From manufacturing to material handling, rotary screw air compressors are an essential element of nearly every industrial sector.

Construction sites use them for:

- Powering jack hammers

- Pneumatic drills

- And concrete sprayers

Manufacturing plants use them for assembly lines, robotic equipment, and material conveying systems.

Automotive facilities use them for spraying paint and operating pneumatic impact wrenches. The oil and gas industries use them for pipeline boosting and gas gathering in harsh environments where equipment reliability is non-negotiable.

Food processing facilities require oil-free models for bottling lines and packaging equipment where compressed air contacts products directly.

Pharmaceutical manufacturing demands the same oil-free technology for tablet coating and sterile packaging to meet strict air quality standards.

Quite possibly the best thing about this technology is that it’s incredibly scalable and adaptable. It can be used in small shops, requiring five-horsepower units delivering 20 CFM (cubic feet per minute), to enormous facilities, requiring thousands of CFM from multiple large-scale units.

Benefits of Rotary Screw Compressor

The best thing about rotary screw compressors is that they are consistent and dependable enough that you don’t need to spend much time thinking about them.

They deliver smooth, continuous air flow that is perfect for a wide variety of industrial applications.

They convert energy more efficiently than reciprocating designs. This can save an incredible amount of money at the industrial level.

Because rotary screw compressors have fewer moving parts than their piston counterparts, they’re also easier to maintain. Industrial screw units routinely operate for many years without major overhauls.

Quieter, smaller, and generally less intrusive, they’re just a better all-around unit for industrial settings. They do cost more on the front end, but are typically cheaper in the context of lifetime ownership thanks to their low maintenance, their high speed, and the fact that they are energy efficient.

Maintenance and Repair of Screw Type Air Compressors

With regular maintenance, compressors can last for a very long time. One of the most important things you can do is simply to check on your air filters regularly in a relatively clean industrial environment.

This might mean monthly checks; in very dusty or strenuous conditions, check them weekly.

Replacing Air Filters

Air filters are typically supposed to be replaced annually. However, if they’re clogged and dirty in a way that restricts airflow, replace them sooner.

Dirty filters waste energy and harm the overall efficiency of the machine. For oil-lubricated models, change the oil and oil filter every 2,000 to 4,000 hours for a mineral oil filter, or up to 8,000 hours for synthetic compressor oils. Replace separator elements every 4,000 to 8,000 hours depending on your operating conditions.

Cleaning Your Compressor

You can also clean your compressor monthly by blowing out dust from after-coolers and heat exchangers using compressed air or appropriate solvents.

Most ongoing maintenance requirements are simple enough that they can be handled in-house. For major repairs like rotor replacement, bearing changes, or full motor rebuilds, you’ll need a factory-trained technician.

For maximum efficiency, consider stocking basic spare parts like filters, an extra gear drive, belts, and oil so that you’re ready at all times to keep your compressor going.

Troubleshooting Common Issues

Compressors will usually run without much need for effort on your end. When they don’t, troubleshooting the problem is often simple enough to be handled in-house.

Low Pressure

Inadequate pressure delivery is a frequent and easily solvable issue, generally indicative of a clogged filter. It may also mean that there is a leak in your lines. You can identify that by listening for hissing sounds near the compressor.

Oil in Your Air Lines

If you’re getting a lot of oil in your air lines, it’s an indication that your oil separator has failed. In this case, check the separator pressure differential.

Strange Sounds or Vibrations

When your compressor begins to make unusual sounds or it starts vibrating incoherently, it’s suggestive of mechanical problems.

Worn bearings cause grinding noises and can destroy rotors if not addressed quickly. Verify the unit is securely bolted to its foundation—loose mounts create excessive movement and noise.

Compressor Won’t Start

If the compressor won’t start, verify power supply and check circuit breakers, fuses, and disconnect switches.

- High temperature switches

- Low oil pressure switches

- Motor overload protection

Can prevent starting. Reset these after identifying why they tripped.

While it’s often possible to troubleshoot problems yourself, calling in a technician is a good way to get your compressor running again quickly and with minimal disruption to operations.

Conclusion

Rotary screw air compressors are true industrial workhorses. For simple efficiency and unfailing reliability, there is no better option on the market.

Never is the phrase “time is money,” more true than when it is applied to the industrial setting. Yes, rotary screw air compressors cost a little more on the front end than alternative products. For uninterrupted precision and efficiency, there is no better option.

Now that you understand how these machines work, you’re better equipped to maintain them properly and maximize their lifespan. Start implementing the maintenance practices we covered, and your compressor will deliver decades of dependable service.

Ready to upgrade?

At GiantAir Compressor, we specialize in providing high-quality rotary screw air compressors for industrial applications across every sector. With years of experience helping facilities optimize their compressed air systems, we understand what it takes to keep your operations running smoothly.

Whether you need an oil-free compressor for food processing, a high-capacity twin screw system for manufacturing, or expert guidance on maintenance best practices, we’re here to help.

Contact us today to discuss your compressed air needs or download our product catalog to explore our full range of industrial compressor solutions.